Part 2 (Spring 2006)

Christmas over and time to get back on with the rebuild. It’s a bit colder

now and I wish I had a heated workshop, but I haven’t so get on with it

and stop moaning.

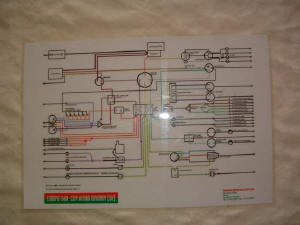

The

installation of the wiring loom was the next job on the agenda.

Richard

sent me down the loom complete with a laminated A3 coloured wiring

diagram, which I found really useful and easy to understand. The loom

comes in 2 bits, 1 for behind the dash the other for the remainder of the

car, therefore, you can completely finish wiring up the dash before

putting it in the car.

Richard

sent me down the loom complete with a laminated A3 coloured wiring

diagram, which I found really useful and easy to understand. The loom

comes in 2 bits, 1 for behind the dash the other for the remainder of the

car, therefore, you can completely finish wiring up the dash before

putting it in the car.

It

took us all of January to fit the wiring loom and associated bits and

pieces, but that is not as bad as it sounds because as much time was spent

drinking coffee and warming up as was spent actually doing any work. It

probably did not take any more than 30 man hours in reality from start to

finish which I do not think is too bad considering my lack of knowledge

and lack of any specific tools/meters. The whole job was done with the aid

of a 12v bulb holder, 12v bulb and 2 bits of wire attached to the

terminals. To find an ‘earth’ you simply connect one wire from the bulb

holder to a known ‘live’ and the other to what you are looking for, when

the bulb lights up you have an ‘earth’.

The

weather turned even colder for February and March and we did not work on

the car at all, as the next job was to fit the carpets and a temperature

of above 5 degrees was needed. I think if I were to plan another rebuild I

would start at Easter and set a finish date for Christmas, that way the

best of the weather could be had for the complete job and no break would

be necessary. Using contact adhesive the underlay/sound insulation needs

to be fitted first, followed up by the carpets. I purchased a new carpet

set, from Richard, but there is still quite a bit of trimming required to

fit the set. It is not as easy as I thought it would be and uses more

contact adhesive than I originally thought. I used 7.5 litres to fit the

underlay, carpet set and roof lining.

The

next job was to fit the seat belts, which was quite straight forward

at this point. However, lining up the bobbin to the centre tunnel fixing

had previously given me a bit of trouble and true to form had to be

undertaken on two occasions. This is because I first

of all set it in position when I remounted the body to the chassis.

However, the body settled on the chassis over time and it was half a hole

out when I double checked it some months latter. Therefore I had to cut

the bobbin out, reposition it and fibreglass it back in the right

position.

forward

at this point. However, lining up the bobbin to the centre tunnel fixing

had previously given me a bit of trouble and true to form had to be

undertaken on two occasions. This is because I first

of all set it in position when I remounted the body to the chassis.

However, the body settled on the chassis over time and it was half a hole

out when I double checked it some months latter. Therefore I had to cut

the bobbin out, reposition it and fibreglass it back in the right

position.

The

lesson learnt here is do not position the bobbins until the body has

settled on the chassis and do it just prior to fitting the seat belts. I

believe it is important to allow the body to settle otherwise the body

will be exerting undue pressure on the seatbelt

fixings and will ultimately break them out. Last but not least the seats

were fitted and the cabin work was complete.

The

final works to be undertaken revolved around making the vehicle

roadworthy. I had agreed with Richard to trailer it up to his workshop,

for him to give my work the once over, for the geometry to be set up and

road tests undertaken. This took just over a day and I drove it back home.

Richard found a couple of things he was not happy with, the gear linkage

and handbrake.

The

gear linkage was not really a fault with my workmanship, but more a design

flaw. You will see most road test reports state that the gears are

difficult to get. However, Richard does a rose jointed conversion kit for

the rear end which makes getting the gears allot easier. He fitted this

and I must agree that it is now no more difficult to change gear in the

Europa than it was with the Elise.

The

handbrake is notoriously difficult to get working properly, I had added a

bit which I thought improved the situation, however, Richard was not happy

with it and took it out, returning it to its original state.

The

handbrake is notoriously difficult to get working properly, I had added a

bit which I thought improved the situation, however, Richard was not happy

with it and took it out, returning it to its original state.

I

have now covered just over 350 miles with the car since the rebuild and

there are a couple of things I am not altogether happy with. The brakes

are not as good as I would like and I may fit a disc conversion kit to the

rear end. I have a vibration between 41 and 55 mph, possibly the gearbox

(which I didn’t overhaul) or the infamous rear bearings.

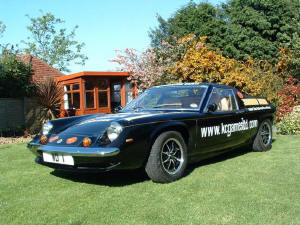

On

the left is a picture of the completed car.

Summary

I

started out to rebuild the Europa with no specific knowledge, tools or

workshop. I can confirm that it is possible to achieve it, however, it is

frustrating at times, costs considerable sums and takes a fair amount of

effort to complete the task.

It

has taken approximately 700 man hours to do. However, I have had to learn

by my mistakes and do some things several times before getting it right.

Richard gave me a ‘ball park’ figure for the works I have carried out

(£14,000) therefore I have been saving about £20/hour.

It

has cost just over £10,000 on parts, which is more than I hoped or

budgeted for, but on the positive side, the car looks better than I

thought it would and should last for quite some time.

I

would not have been able to complete it without Richards help and most

times I phoned to order something I had a question of ‘how do you do

this?’. I have phoned Richard about 40 times throughout the rebuild and I

thank him for his patience.

If

you are considering undertaking a rebuild yourself and like me have no

prior experience I hope you find this report interesting and informative.

If you want one piece of advise, do not try to rebuild the rear hubs

yourself, send them away to Richard or somebody else who knows what they

are doing and save your self all the trouble, it will also shield your

nearest and dearest from a barrage of foul language.

Below you will see another view of the completed car (04/05/06).